Cov khoom ntawm tungsten carbide pas nrig thiab nws daim ntawv thov tungsten carbide los yog cemented carbide muaj ntau yam zoo xws li siab hardness, zoo zog, zoo hnav thiab corrosion kuj thiab salient stability nyob rau hauv siab kub txawm nyob rau ntawm 500 ° C.Nws tseem tsis tau hloov pauv thiab txawm tias nyob rau ntawm 1000 ° C muaj qhov siab hardness.

Cemented Tungsten Carbide rods yog sintered hauv HIP Rauv thiab yog ua los ntawm 100% nkauj xwb raw khoom uas suav nrog WC thiab CO.

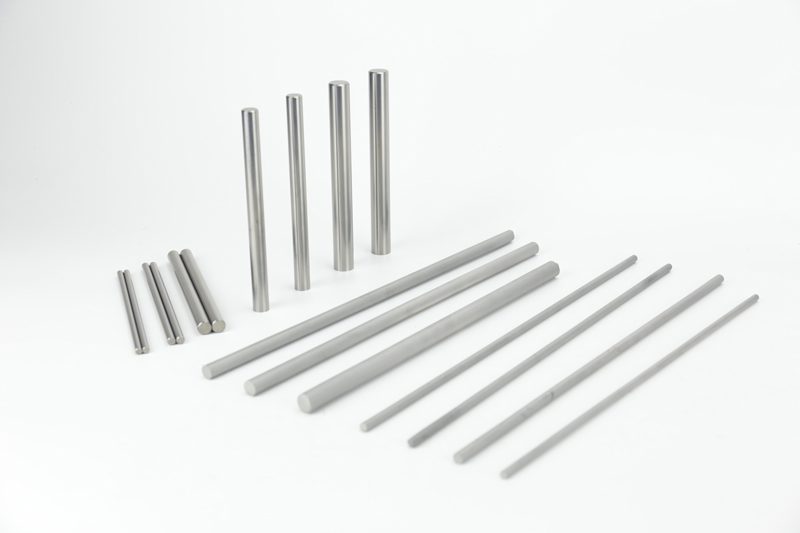

Feem ntau muaj peb hom cemented tungsten carbide rods xws li PCB pas nrig, pas nrig, thiab pas nrig.

Feem ntau ntawm nws cov ntawv thov yog nyob rau hauv kev tsim cov cuab yeej txiav rau hlau, nrog rau cov ntoo, yas, thiab lwm yam ntaub ntawv thiab kev lag luam uas xav tau cov qib siab hardness, hnav tsis kam, thiab corrosion kuj.

Tungsten carbide pas nrig muaj ntau qhov tshwj xeeb zoo, nrog rau cov qib siab hardness thiab lub zog, zoo heev tiv taus hnav thiab corrosion, thiab zoo kawg li stability txawm tias thaum kub kub.Cam khwb cia hlau, nonferrous hlau, yas, tshuaj fiber ntau, stainless hlau, thiab siab manganese hlau tsuas yog ib co ntawm cov ntaub ntawv uas yuav raug txiav nrog cov cuab yeej no.Tsis tas li ntawd, nws tuaj yeem siv los ua cov cuab yeej drilling, cov cuab yeej mining, hnav qhov chaw, precision bearings, nozzles, thiab hlau pwm, thiab lwm yam.

Nov yog qee cov kauj ruam ntawm kev tsim cov tungsten carbide rods.

1) Qib Tsim

Qib ua los ntawm peb lub Hoobkas: SK10, SK30, SK35B, SK35, SK45 thiab lwm yam.

Pom zoo Qib txoj cai rau daim ntawv thov ntawm tungsten carbide rods.

2) RTP Pob Zeb Milling

Lub pob zeb sib tsoo muaj peev xwm tsim cov hmoov nplej ntawm txhua qhov loj, nrog rau cov hmoov zoo thiab ultra-nplua los ntawm cov khoom sib xyaw ntawm WC hmoov, cobalt hmoov, thiab cov khoom siv doping.

Txau-Drying txheej txheem

Txhawm rau lav tias cov khoom siv huv si huv si, cov pej thuam prilling yog txau nrog cov tshuaj tsuag kom qhuav.

3) Extrusion lossis Direct Pressing

2 txoj hauv kev los tsim cov carbide rods.

4) Kev ziab kom qhuav

5) Sintering

Cov hniav tau txais kev kho cua sov ntawm qhov kub ntawm 1500 degrees Celsius rau 15 teev.

6) Machining

Cov neeg siv khoom xav tau H5 / H6 hauv av nto, ces peb yuav ua cov carbide rods nrog centerless sib tsoo.

7) Kev Ntsuas Zoo thiab Kev Tshuaj Xyuas

Txhawm rau kuaj qhov ncaj, qhov ntau thiab tsawg, thiab lub cev ua haujlwm zoo li TRS, Hardness thiab carbide rods tsos thiab lwm yam.

8) Ntim

Ntim carbide rods hauv lub thawv yas nrog daim ntawv lo rau nws.

Post lub sij hawm: Mar-04-2023